To remember the 8 wastes, think DOWNTIME.

Our people are empowered.

Lean construction leaders.

Our regional AGC CM Lean professionals are members of the LCI community of practice in the areas in which we serve.

- PLAN—to identify and analyze the problem.

- DO—develop and implement a solution.

- CHECK—to evaluate the results.

- ACT—to adopt and/or update the necessary standards, abandon the process change or run through the cycle again.

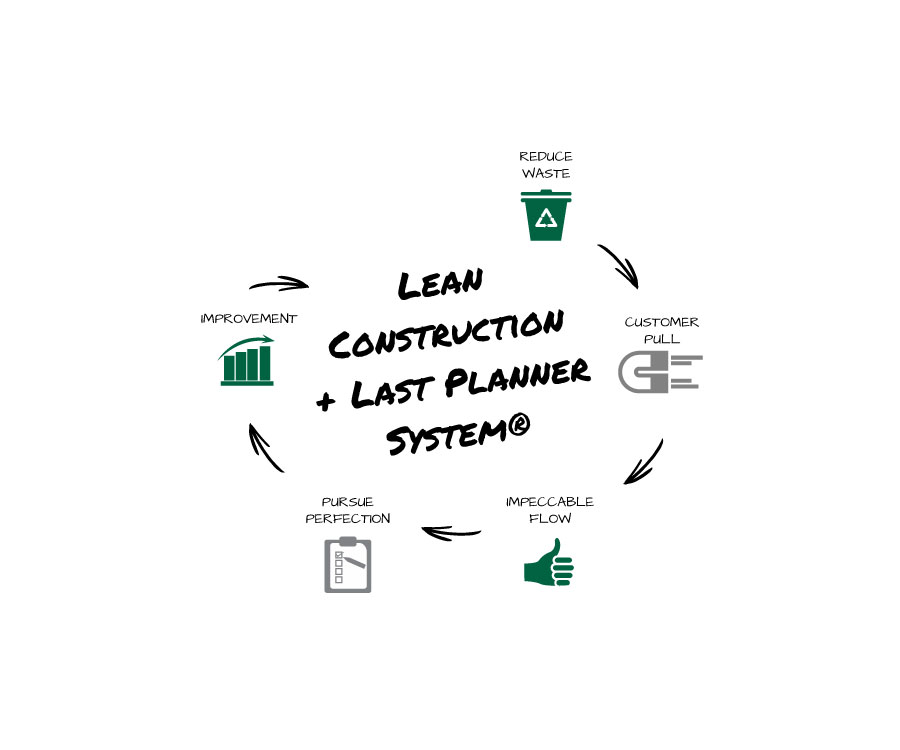

LeChase embraces a lean culture that is centered around collaboration and planning, providing efficient workflow from conception to completion with the elimination of wastes.

Lean culture at LeChase.

Our focus is on improving safety, quality and overall value for our customers.

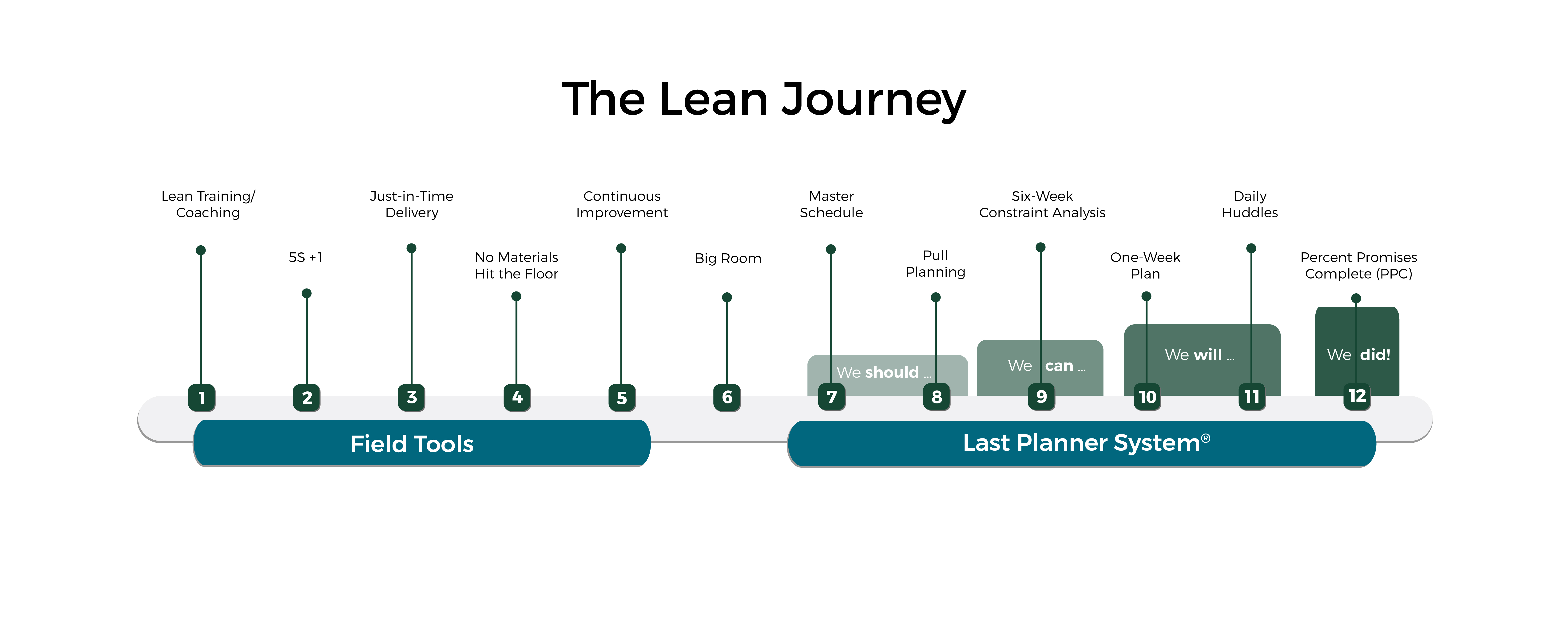

We employ 5S+1, just-in-time delivery, no materials hit the floor, The Last Planner System and continuous improvement.

Eliminate work waiting for workers and workers waiting for work.

Provide predictable and reliable workflow.

See Our Story: River's Casino & Resort